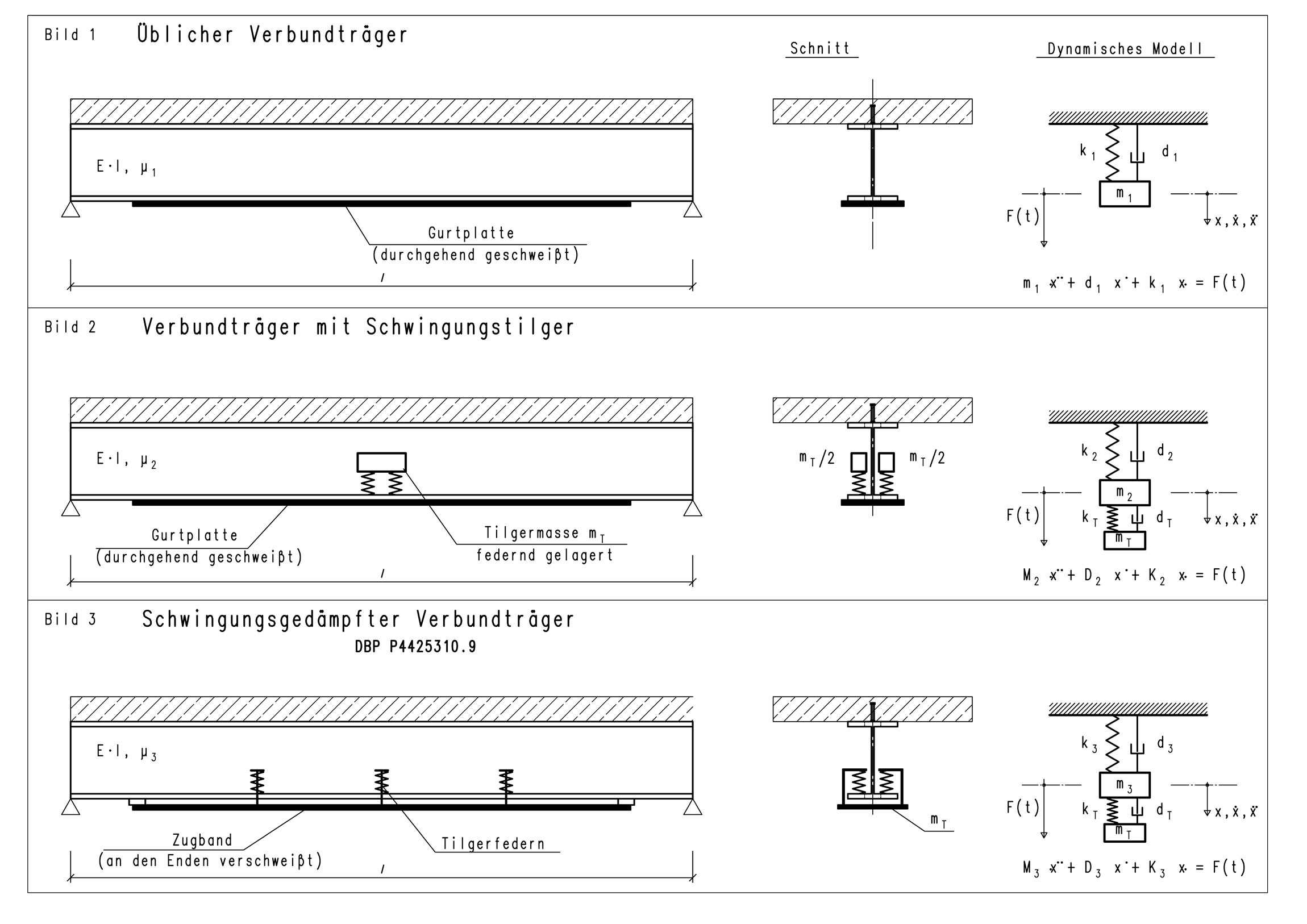

To increase the natural frequency to 5 Hz, the bottom chord of the girder was reinforced with an additional cover plate during the first construction phase, increasing the weight of steel to approximately 18 tonnes per girder. Despite achieving a natural frequency of 5.2 Hz, the vibration behaviour was not ideal – people experienced discomfort due to the low self-damping.

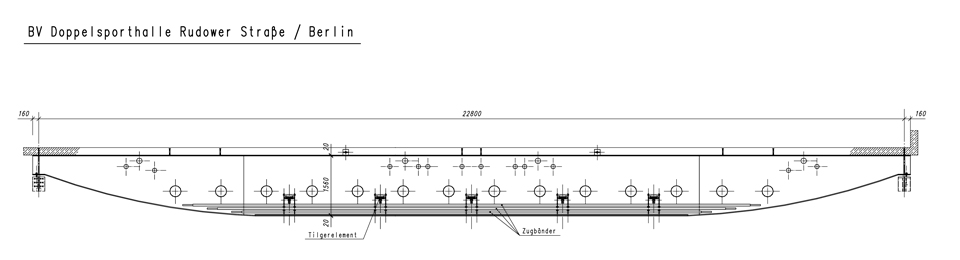

So we adopted a different approach during the second phase of construction and used the vibration-damped composite beams for the first time.

Due to the increased system damping, the optimised beams achieved a natural frequency of 3.8 Hz, resulting in optimal dynamic behaviour without perceptible vibrations. This solution also decreased the weight of steel by around 45 percent to approximately 10 tonnes per beam.